Technological options

Technology

- Proposal of welding technology, particularly with respect to deformation and inner stress of the weldment

- Proposal of a method to minimize the internal stress to ensure long-term dimensional stability of the product

- Optimization of the design proposal of the weldment considering the welding technology with the aim of price optimization

- Proposal of the way and method for testing weldments

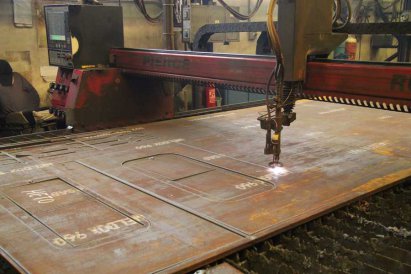

Material cutting

- 3× power saw (profiles with dimensions of max. 250 mm x 250 mm)

- 2× CNC flame cutter RUR 3500 (sheets with thickness 10 mm to 200 mm, maximum dimension of the metal sheet 3000 mm x 12000 mm)

- Burning sheets 4-15 mm, performed on our contractors´ laser with within a radius of max. 20 km

Straightening sheets

- Continuous straightener (sheet thickness 6 mm to 12 mm depending on material quality, maximum sheet size of 3400 mm x 10000 mm)

Blasting

- Continuous blast (chamber size 450 mm x 1500 mm, maximum length of blasted part 10000 mm)

- Blast booth with rail track (rail car capacity 10000 kg, booth dimensions L × W × H: 12000 mm × 6,000 mm × 4,000 mm)

Bending

- CNC press brake ESPECTO 250 (width 3000 mm, pressing force of 225 tons)

- CNC press brake SAFAN (width 4000 mm, pressing force of 250 tons)

Roll bending

- Roll bender breadth max. 2000 mm, thickness max.10 mm.

- Larger and stronger parts done by cooperation, max. 20 km radius, on demand

Planing

- 1 × gantry planer (maximum workpiece dimensions 1250 mm × 1200 mm × 8000 mm)

Welding

Welding of structures and components from low - carbon, fine grain and high strength steels up to S960 quality with the application of preheating or reheating according to DIN 18800-7 standard and according to ČSN EN 1090-1:2009.

- Welding of pressure vessels according to directive PED 97/23/EC for specific applications

- Welding of parts of railway vehicles according to DIN EN 15085-2 certificate

- Welding of sheet metal generally thicker than 4 mm

We will propose the most suitable welding process and we will prepare WPS or qualify WPQR.

- 20 × welder Fronius TPS 5000

- Lorch welders

- The maximum size of the weldment 2 m × 3 m × 10 m

- Maximum weldment weight 10 tons up to 6 m and 13 tons with a length over 6 m

- Qualified welding procedures reviewed annually by working trial according to DVS 1702

Construction of weldments – locksmithing

Assembly of weldments without jigs, using both simple and sophisticated jigs for mass production.

Using locksmith workplaces with large assembly plates, positioners and using using of free areas.

Crack detection

- Visual, magnetic, capillary, ultrasonic or radiographic testing of welds

- Compressed air pressure test (test pressure up to 15 bar)

- Leakage inspections by filling the vessel with water to a volume of 2 m³

Heat treatment

- Electric resistance furnace for annealing to eliminate internal stress (maximum size of the weldment 2100 mm × 900 mm × 450 mm)

- Annealing for inner stress relieving for larger parts is provided for contractual partners within a distance of 20 km, including the possibility to secure the atypical annealing diagrams

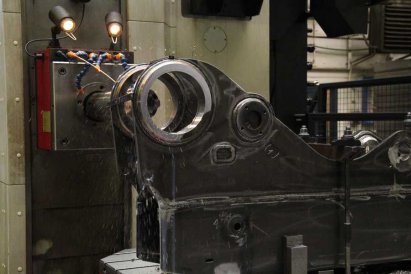

Drilling, boring and milling

Maximum workpiece weight 10000 kg. Maximum workpiece size 2000 × 2000 × 8000 mm.

- Horizontal boring Fermat WFT 13 CNC (with turntable; maximum range in axes xyz 5,000 mm × 2,500 mm × 1,700 mm)

- Horizontal boring machine TOS WHN 13.8C (with turntable; maximum range in axes xyz 3,500 mm × 2,000 mm × 800 mm)

- Horizontal boring machine TOS WD 130 (maximum travel range of xyz 8,000 mm × 1,800 mm × 400 mm)

- Horizontal boring Fermat TK 6511 (with turntable; maximum range in axes xyz 2,500 mm × 1,500 mm × 550 mm)

- Horizontal boring machine TOS WH 10 NC (with turntable; maximum range in axes xyz 1,500 mm × 1,500 mm × 550 mm)

- Horizontal Machining Center Hitachi Seiki HG 500II (with turntable and two pallets; maximum range in axes xyz 710 mm × 680 mm × 600 mm, maximum load of a pallet 800 kg)

- Horizontal boring machine WRD 130q with plate array, the maximum range of 9000 x 3000 x 1700 mm – from IV./2014)

Turning

- 3× universal centre lathe (maximum workpiece dimensions: Ø250 mm × 2000 mm)

Dimensional inspection and measurement

- Weldments 2 m × 3 m × 10 m accuracy of 1 mm

- Processing Length Measures up to 2m accuracy of 0.05 mm

- Holes up to 500mm accuracy of 0.01 mm

- Geometry of the parts – possibility of CCM measurement accuracy of 0.02 mm

Finishes

- degreasing and paint booth with a manually controlled hanging groove (hanger bearing capacity 250 kg)

- degreasing and paint booth with a rail track (booth dimensions L × W × H: 12 000 mm x 6000 mm x 4000 mm rail car capacity 10 tons)